The analysis hut is mostly far from the inspection personnel duty room, or in a dangerous area, and most of the inspection is not timely, the judgment of pre-failure is not enough, and the on-site inspection is not convenient at night. When the instrument is in the sub-health working state, if it is not restored to the normal working level in time, it is easy to have the consequences of instrument failure, data inaccuracy and even production shutdown.

The remote intelligent monitoring and analysis cabin adopts a remote intelligent monitoring system to monitor the working environment, carrier gas pressure, and pre-processing status of life safety instruments and online analysis instruments in the cabin to achieve "unmanned inspection". When abnormal data occurs, the solution is automatically analyzed and ready to arrive at the scene to solve the problem.

Through the 3-level monitoring and maintenance, the remote intelligent monitoring system can effectively prevent the invisible failure of the analysis system, greatly reduce the on-site maintenance pressure, and effectively ensure the stable running time of the analysis system.

The first stage: it can realize the centralized collection of temperature, humidity, pressure, combustible gas concentration and toxic gas concentration inside the cabin, and display it on the outer wall of the analysis cabin, eliminating the opening and unpacking inspection procedures of inspection and maintenance personnel, and shortening the inspection time.

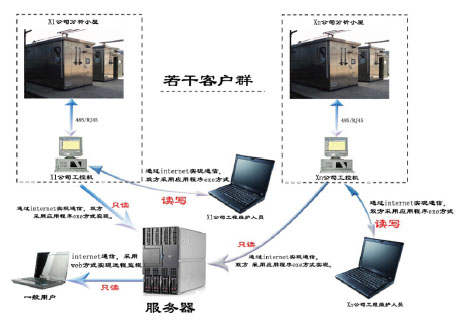

The second level: remote intelligent monitoring and analysis hut will centrally collect and display data through Ethernet transmission to the user's office or DCS control room monitoring server. The special intelligent monitoring software set up on the server makes intelligent judgment on all data. When there is an anomaly, the sound and light alarm in the local cabin and control room will be activated in time, and the maintenance personnel will be notified through mobile phone SMS. To achieve effective prevention of analysis system failures, eliminate hidden dangers in advance.

The third level: Install a server in the manufacturing plant, send the data required for remote diagnosis and maintenance to the server through the Internet network remote network, and the technical experts diagnose the data, and send the diagnosis results and processing plan back to the user monitoring server, to help users solve on-site faults anytime and anywhere.

Related products